Functioning Procedure For The Continuous Pyrolysis Plant As Well As The Advantages It Gives You

4

About :

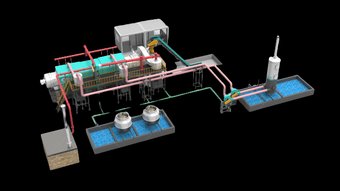

The words ‘pyrolysis’ suggests the concurrent chemical and physical modifications in the organic matter, which can be exposed to extremely high temperatures. A continuous waste tire plant is actually a unique tire recycling machine which utilizes the pyrolysis process as a way to recycle discarded tires into oil and carbon. The main advantage of these appliances is because they will make fuel oil from waste plastics inside an eco-friendly way. Due to this, these are integral with regards to handling waste plastic disposal problems.

A continuous pyrolysis plant uses a computerized system that is certainly controlled remotely using a PLC (Programmable Logic Controller) or computer system. Together with the constant and automated input and discharge structure, it could retain the pyrolysis system performance 24/7. Here we are going to be checking out the functioning technique of the continuous pyrolysis plant and the advantages it offers.

The Working Process

-A plastic grinder can be used for shredding every one of the plastic available into tiny plastic pieces. These pieces are then inserted to the pyrolysis plant from the feeding door.

-The feeding door of your machine is essentially designed with an interior screw to help you convey the moment plastic pieces easily to the first reactor in the plant. The plastic may then be put through extremely high temperatures throughout the first reactor, for the second one, and so forth till all available plastic has gone through pyrolysis. From that point, the resulting carbon black powder is going to be discharged automatically into an unconnected carbon black tank.

-The resulting oil gas will be cooled completely using the circulation of water, whilst the additional pyrolysis has goes through recycling with the pipes and into the burners for that heating process to be repeated. Usually, a continuous plant comprises a water circulation structure as well as an extra pyrolysis gas recycling structure. All of these help you save on water and energy bills. This may view you make huge profits.

Advantages

-High oil output and large capacity: Given how the system enables continuous input and discharging, combined with several reactor designs, the continuous plant can process vast amounts of waste tires every day. Given that it gives you total pyrolysis to waste tires, the continuous plant can produce large oil amounts.

-Reduced labor cost: As aforementioned, a fully continuous plant is run by a computerized feeding and a PLC system, and also a discharging system. As a result, you merely need to have a few personnel to operate the PLC or computer system. The continual process also permits you to save time and expenses incurred in covering bills.

-Long working lifespan: Indirect heat is commonly used when heating the reactors in the continuous plant. Because of this, the reactor won’t get damaged much, which can enable it to execute its functionality for years.

-Internal rotating: This internal rotating allows for continuous operation of the machine. In external rotating systems, you’ll have to replace the seal material after a couple of days. Which means that when working with this system, this won’t be described as a bother.

Tags :

Their limit for today is $0!

Comments:

Reply:

To comment on this video please connect a HIVE account to your profile: Connect HIVE Account