Exactly What Is An Oil Sludge Pyrolysis Plant?

0

About :

Oil sludge is produced through drilling, refining, and exploration of various oil resources. It consists of sludge, water, and oil, which could increase environmental pollution if not processed properly. Oil sludge is also a valuable resource which offers the chance to produce money. This is the reason the reasons manufacturers are now buying the oil sludge pyrolysis plant.

Since unprocessed sludge poses a danger in terms of the nearby environment, oil sludge treatment is among the top investments for non-governmental, governmental, and private organizations. These treatment plants not just produce a valuable supply of fuel oil but is additionally an excellent way to reduce the hazards associated with oil-sludge pollution.

Possibilities together with the Oil Sludge Pyrolysis Plant:

Oil sludge treatment plants feature an automatic feeding-system that uses a direct condensation method that cools the gas right into a liquid. Each of the exhaust gas and wastewater are processed by a special machine, which avoids polluting the nearby environment.

The oil sludge pyrolysis plant includes a pressure gauge along with an automated warning device which makes certain that the plant is safe to use and can alert the operator if something fails.

How Does A Pyrolysis Plant Assistance To Treat Oil Sludge?

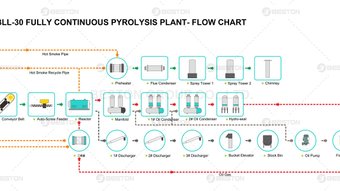

Prior to the invention of the oil sludge treatment plants, it absolutely was once a complicated process to deal with oil sludge. Oil sludge is definitely the by-product of oil refinery and drilling and is comprised of a mix of oil and water. The pyrolysis plant for oil sludge separates the oil through the water, turning the oil into a usable product. The oils sludge pyrolysis plant includes an oil condenser, pyrolysis reactor, hydro-seal, de-casting system, as well as an oil tank.

The Design Of The Oil Sludge Pyrolysis Plant:

The main components associated with exhaust gas that cannot be liquefied, include the alkanes class C1 to C4. The direct burning of such alkanes poses many risks. The pyrolysis plant features a design whereby the gas first passes via a water-seal. The gas is going to be trapped in the very first seal before it is used as fuel for the gas burner, which happens to be contained inside a safety device.

These systems also have a hydro-seal which stops the flame from burning back, while removing impurities, sulfur and cleans the desulfurization gas.

These devices also come with built in operating technology to handle any bugs along the way of production. In addition, it incorporates a pressure gauge and thermometer to observe pressure and temperature.

It also used still another-generation heating method that combines excellent features of both indirect and direct heating to make certain a safer operation.

Final Thoughts

The oil sludge pyrolysis plants can be bought in 3 types, including the fully-automatic oil sludge pyrolysis plant, semi-automatic oil sludge plant, and the batch oil sludge pyrolysis plant. The plant which fits up to your requirements is going to be based on the volume of oil sludge that you intend to process. Crude oil sludge pyrolysis plants have become a stylish investment chance of many organisations that deal using this type of waste.

Tags :

Their limit for today is $0!

Comments:

Reply:

To comment on this video please connect a HIVE account to your profile: Connect HIVE Account